JK/JKB Mine Hoist

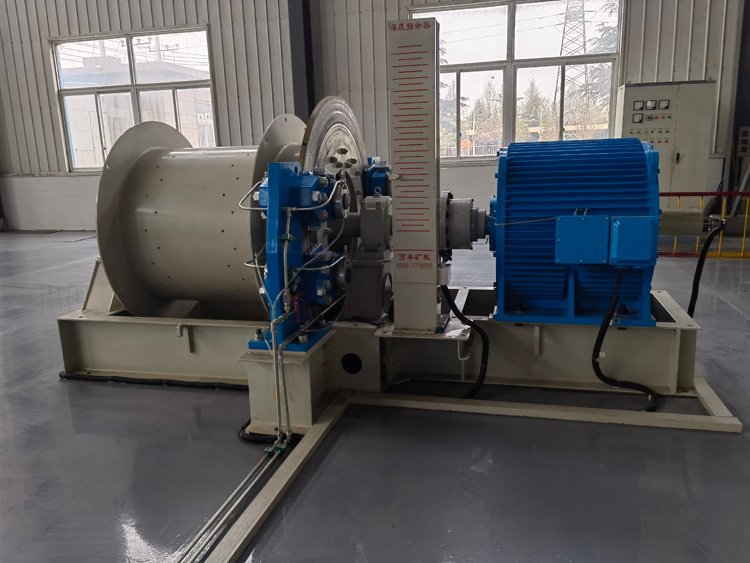

JK Mine Hoist

适用范围:适用于煤矿、金属矿、非金属矿山地面或地下的斜巷、垂直井中提升卸料和人员。

JKB explosion-proof mine hoist

适用范围:主要用于煤矿、金属矿、非金属矿山的垂直或倾斜井道中提升煤炭、物料、提升人员和下放材料及设备,也可用于其它牵引和运输。

2JK Mine Hoist

Scope of application: Suitable for the inclined tunnels and vertical tunnels on the ground or underground of coal mines, metal mines and non-metallic mines for lifting materials and personnel.

JKZ single rope winding type well drilling hoist

JKZ Well Drilling Hoist

Product Introduction: Classification Structure Type The structure type of the chiseling and lifting machine is a drum winding type, which consists of a motor, a reducer, a spindle device (including the spindle, the drum and the base, etc.), a disc brake, a deep.

2JKZ Well Drilling Hoist

Product Introduction: The structure of the well drilling hoist is a reel winding type, which consists of a motor, a reducer, a main shaft device (including the main shaft, a reel and a base, etc.), a disc brake, a depth indicator, a hydraulic station and an electronic control system.

JTP type mining hoist winch

JTP type mining hoist winch

Scope of application: Mainly used in inclined tunnels or small vertical tunnels in coal mines, metal mines and non-metallic mines to lift materials or personnel.

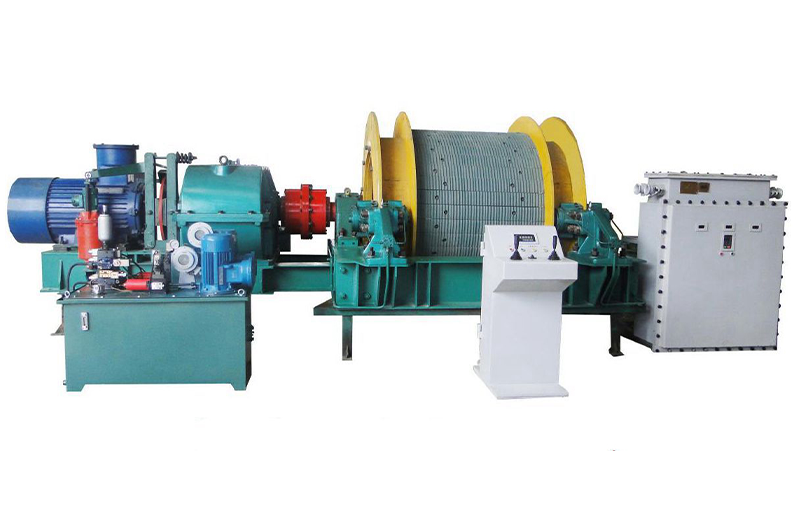

2JTP type mining hoist winch

Product Introduction: 2JTP series products are designed and manufactured according to Q/HBWF002 “JTP type mine hoisting winch” enterprise standard, AQ1033-2007 “Safety Inspection Specifications for JTP Type Hoisting Winch for Coal Mines”, JB/T7888-2010 “JTP Type Mine Hoisting Winch” industry standard and “Coal Mine Safety Regulations”.

JTPB explosion-proof mining hoisting winch

Scope of application: JTP and 2JTP series mining hoisting winches are mainly used in inclined tunnels or small vertical tunnels in coal mines, metal mines and non-metal mines to lift materials or personnel.

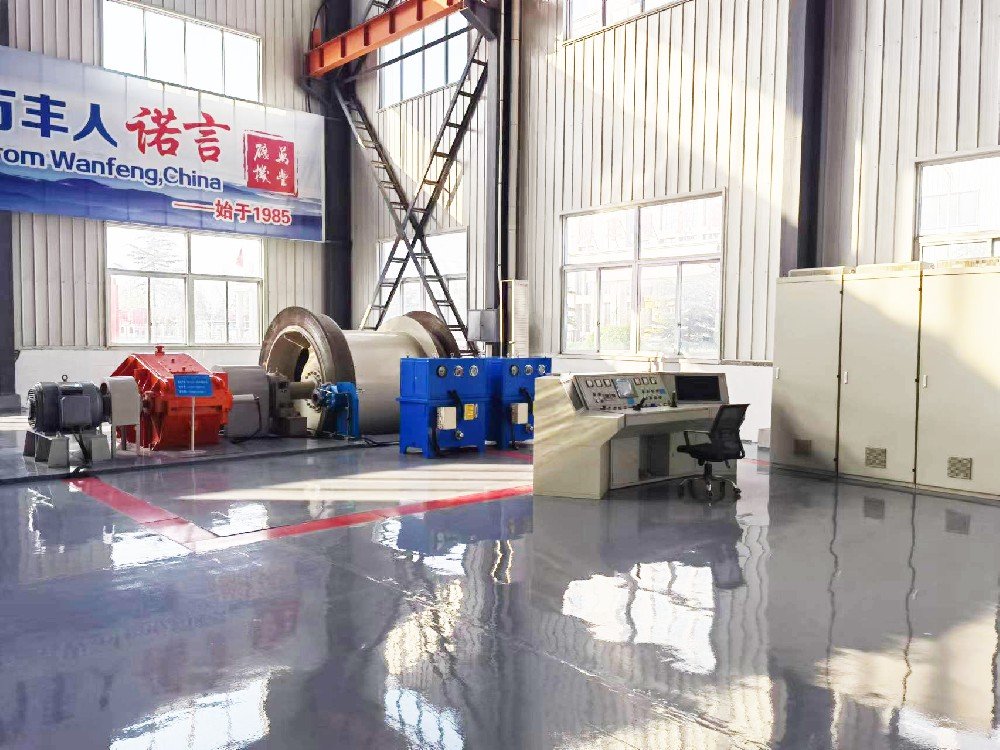

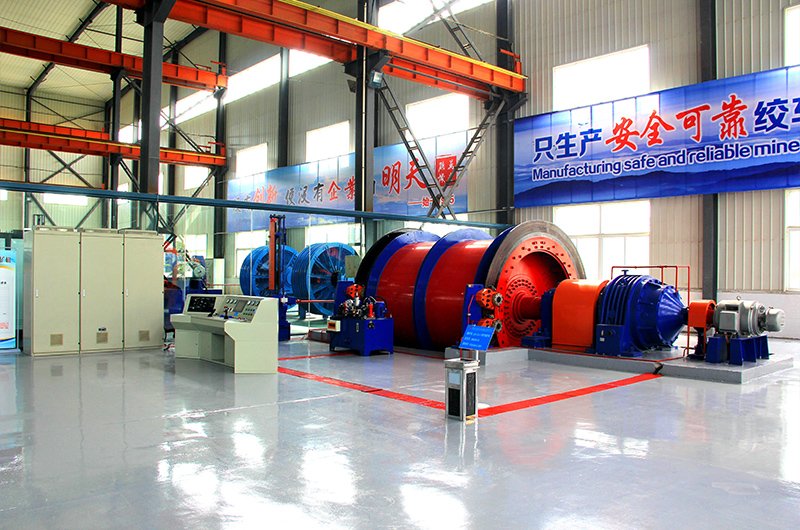

JKMD Mine Hoist

JKMD multi-rope friction mining hoist

Product Introduction: JKM multi-dimensional friction hoist series is designed and manufactured in accordance with the enterprise standard “Multi-rope friction hoist for coal mines” AQ1036-2007 “Safety Inspection Specification for Multi-rope Friction Hoists for Coal Mines” and GB/T10599-2010 “Multi-rope Friction Hoists” and “Safety Regulations for Coal Mines”.

JKMD multi-rope friction mining hoist

Product introduction: JKMD and JKM multi-rope friction hoist series products are designed and manufactured in accordance with Q/HBWF006 “Multi-rope friction hoist” enterprise standard, AQ1036-2007 “Multi-rope friction hoist for coal mines, safety inspection specification” and GB/T10599-2010 “Multi-rope friction hoist” standard and “Coal Mine Safety Regulations”.

JKMD multi-rope friction mining hoist

Product introduction: JKMD and JKM multi-rope friction hoist series products are designed and manufactured in accordance with Q/HBWF006 “Multi-rope Friction Hoist” enterprise standard AQ1036-2007 “Safety Inspection Specifications for Multi-rope Friction Hoists for Coal Mines” and GB/T10599-2010 “Multi-rope Friction Hoists” standards and “Coal Mine Safety Regulations”.

JZ type sinking winch (band brake)

JZ Series Shaft Drilling Winch

Product introduction: The series of shaft winches are mainly used for suspending hoisting plates, water pumps, water pipes, grouting pipes, air cylinders and other excavation equipment and tensioning and stabilizing ropes when digging shafts in coal mines, metal mines and non-metallic mines. The winch is mainly used to replace the tail rope connecting the two cages of the hoist; and it is very good at replacing flat ropes, and can also be used as a shaft winch, and its performance is the same as that of the shaft.

2JZ Series Shaft Drilling Winch

Trial scope: Mainly used for suspending hoisting plates, water pumps, air cylinders, compressed air cylinders, grouting pipes and other excavation equipment and tensioning and stabilizing ropes in shaft excavation projects in coal mines, metal mines and non-metallic mines. It can also be used for other lifting heavy objects below and on the ground.

JZ-40/1500 (1800)

Product introduction: The series of shaft winches are mainly used for suspending hoisting plates, water pumps, water pipes, grouting pipes, air cylinders and other excavation equipment and tensioning and stabilizing ropes when digging shafts in coal mines, metal mines and non-metallic mines. The winch is mainly used to replace the tail rope connecting the two cages of the hoist; and it is very good at replacing flat ropes, and can also be used as a shaft winch, and its performance is the same as that of the shaft.

JZ sinking winch (disc brake)

.png)

JZ sinking winch (disc brake)

Product Introduction: J2 series shaft-drilling winches are designed and manufactured in accordance with the People’s Republic of China’s safety production industry standard AQ 1031-2007 “Safety Inspection Specifications for Shaft-drilling Winches for Coal Mines” and GB/T 15112-2007 “Shaft-drilling Winches”.

2.png)

JZ sinking winch (disc brake)

Product Introduction: J2 series shaft-drilling winches are designed and manufactured in accordance with the People’s Republic of China’s safety production industry standard AQ 1031-2007 “Safety Inspection Specifications for Shaft-drilling Winches for Coal Mines” and GB/T 15112-2007 “Shaft-drilling Winches”.

JZA Safety Ladder Winch

ZA-5/1000(1300) Safety Ladder Winch

Product introduction: JZA-5/1000(1300) safety ladder winch is a necessary safety equipment in vertical shaft engineering of coal mines, metal mines and non-metallic mines. It is mainly used for emergency rescue of equipment and personnel under abnormal conditions, when power is on or off. It can also replace the ground construction winch for ground construction and handling and lifting.

ZA-5/1000(1300) Safety Ladder Winch

Product introduction: JZA-5/1000(1300) safety ladder winch is a necessary safety equipment in vertical shaft engineering of coal mines, metal mines and non-metallic mines. It is mainly used for emergency rescue of equipment and personnel under abnormal conditions, when power is on or off. It can also replace the ground construction winch for ground construction and handling and lifting.

Vehicle stabilization control system

产品介绍:

Permanent magnet mining hoist winch

Permanent magnet internal mining hoisting winch

Product introduction: The new generation of permanent magnet synchronous speed regulation technology has a speed regulation range of 0.01Hz~15Hz, which is 100 times higher than the speed regulation accuracy of traditional hoists, making the operation of mining hoisting winches more stable.

Permanent magnet motor direct-coupled mining hoist winch

Product introduction: The new generation of permanent magnet synchronous speed regulation technology has a speed regulation range of 0.01Hz~15Hz, which is 100 times higher than the speed regulation accuracy of traditional hoists, making the operation of mining hoisting winches more stable.

Permanent magnet series JK type mining hoist

产品介绍:永磁电机简介,电机定子由壳体、铁心和绕组组成。装有绕组的定子铁心直接热装在定子壳体内。定子铁心采用优质低损耗电工硅钢片冲压叠片而成,每片硅钢片两面均涂有耐热无机涂层绝缘。整个定子铁心两端用钢环压紧。永磁材料的选择基于机械、加热和磁能退磁的要求,能够保证持续提供提升机工作所需的转矩。

Winch/hoist signal system/electronic control system

Hoist signal system and main control system

Product introduction: Main technical and related requirements for hoisting machine electrical control system and signal control system. It includes technical requirements for design selection, configuration, structure, performance, manufacturing, installation guidance, testing, commissioning, trial operation, training, technical service, maintenance and quality assurance of software system, equipment and its accessories.

High voltage variable frequency speed regulating hoist electronic control system

Product Introduction: The entire electronic control system is divided into three parts: high-voltage frequency conversion speed regulation system, dual PLC network operating system, and intelligent upper-level monitoring system.

Hoist signal system and main control system

The explosion-proof variable frequency electric control system for mine hoists uses a mine-use explosion-proof and intrinsically safe AC inverter as the core equipment, and is equipped with a mine-use explosion-proof and intrinsically safe PLC control box, an intrinsically safe operation table, an explosion-proof display screen, field sensors, an operation box, an audio-visual display screen and other equipment. This system is suitable for underground coal mines and other places containing coal dust, gas or other flammable and explosive gases, and is applicable to underground dark inclined shafts; single-level and multi-level: single-drum, double-drum and other mine hoists. It has the characteristics of compact structure, small size; excellent speed regulation and control performance: safe and reliable, easy to use and maintain, etc.